Umngundo wePlastiki sisixhobo esihambelana noomatshini bokubumba iplastiki kwishishini lokulungisa iplastiki ukunika iimveliso zeplastiki ubumbeko olupheleleyo kunye nobukhulu obuchanekileyo. Ngokweendlela ezahlukeneyo zokubumba, zinokwahlulwa zibe ziindidi ezahlukeneyo zokubumba.

1. Ukubumba i-polystyrene ephezulu eyandisiweyo iyafa

Luhlobo lokungunda olusebenzisa i-polystyrene eyongezelekayo (impahla ye-bead eyenziwe nge-polystyrene kunye ne-agent ekhupha ugwebu) imathiriyeli ekrwada ukwenza imathiriyeli yokupakisha yogwebu yeemilo ezahlukeneyo ezinqwenelekayo.

Umgaqo-siseko kukuba i-polystyrene enokwandiswa inokutshizwa kwi-mold, kubandakanywa neentlobo ezimbini ze-mold operation elula kunye ne-hydraulic straight-th through foam molds zeplastiki, ezisetyenziselwa ikakhulu ukuvelisa iimveliso zokupakisha kwiimveliso zamashishini. Izinto zokwenza iimbumba ezinjalo ziphosa i-aluminium, insimbi engenasici, ubhedu, njl.

2. Ukunyanzeliswa ngundo

Kubandakanya ukubunjwa koxinzelelo kunye nesitofu sokubumba iintlobo ezimbini zokubumba. Ziluhlobo lokubumba olusetyenziselwa ukubumba iiplastiki ze-thermosetting, kunye nezixhobo zabo ezihambelanayo ngumatshini wokushicilela.

Ukunyanzeliswa kwendlela yokubumba Ngokweempawu zeplastiki, ukubumba kushushu kwiqondo lokushisa lokubumba (ngokubanzi 103 ° 108 °), emva koko umlinganiselo wokulinganisa umgubo wokubumba ufakwe kwi-mold cavity kunye negumbi lokutyisa, ukubumba kuvaliwe, kwaye iplastiki ishushu phantsi kobushushu obuphezulu kunye noxinzelelo oluphezulu. Thambanisa ukuhamba kwe-viscous, qinisa kwaye umise emva kwexesha elithile, kwaye ube yimveliso efunekayo imilo.

Umahluko phakathi kokubumba inaliti kunye nokunyanzeliswa kokubumba kukuba akukho gumbi lokutyisa lahlukileyo. Isikhunta sivaliwe ngaphambi kokubunjwa, kwaye iplastiki ifudumala kwigumbi lokutya kwaye ibe yimeko yokuhamba kwe-viscous. Ngaphantsi kwesenzo soxinzelelo, kulungelelaniswa kwaye ugxininiswe kwi-mold cavity ukuze uqine kwaye wenze.

I-compression mold iqulunqwe ubukhulu becala, umngxuma wokutyisa, indlela ekhokelayo, iindawo zokukhupha, inkqubo yokufudumeza, njl. Izinto ezisetyenziswayo xa kusenziwa imibumbo yokucinezela ziyafana nezitofu.

3. Isitofu sokungunda

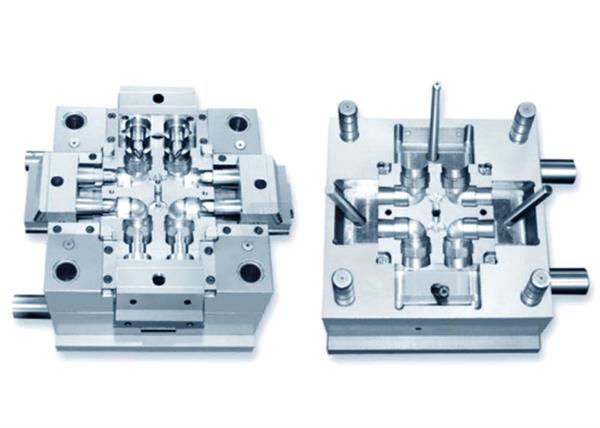

Ikakhulu sisibumba sokubumba esisetyenziswa ngokuqhelekileyo kwimveliso yamalungu e-thermoplastic. Izixhobo zokucubungula ezihambelana ne-injection mold ngumshini wokubumba inaliti. Iplastiki ifudumeza kuqala kwaye inyibilike kwi-barrel yokufudumeza ezantsi kumatshini wokubumba inaliti. Ngaphantsi kokutyhala iplagi, ingena kumgodi wokubumba nge-injection yomatshini wokubumba i-nozzle kunye nenkqubo yokugalela i-mold, kwaye iplastiki ipholile kwaye iqiniswe ukwenza, kwaye imveliso ifunyenwe ngokudiliza.

Ulwakhiwo lwalo ludla ngokuqulunqwa ngamalungu okwenza, inkqubo yokugalela, iindawo ezikhokelayo, i-push-out mechanism, inkqubo yokulawula ubushushu, inkqubo yokukhupha, iinxalenye ezixhasayo kunye nezinye iindawo, kwaye zenziwe ngentsimbi yeplastiki yokubumba. Inkqubo yokubumba inaliti idla ngokufanelekileyo kuphela kwimveliso yeemveliso ze-thermoplastic. Iimveliso zeplastiki eziveliswe yinkqubo yokubumba inaliti zibanzi kakhulu. Ukusuka kwiimfuno zemihla ngemihla ukuya kwizinto ezahlukeneyo zombane ezintsonkothileyo kunye neenxalenye zemoto, zonke zenziwe ngenaliti yokubumba. Enye yezona ndlela zisetyenziswa kakhulu kwimveliso yeplastiki.

4. Vuthela ukungunda

Umngundo osetyenziselwa ukwenza iimveliso zeplastiki ezingenanto (ezifana neebhotile zesiselo, iimveliso zemichiza yemihla ngemihla kunye nezinye izikhongozeli zokupakisha). Uhlobo lokubumba uvuthela ikakhulu lubandakanya ukubumba i-extrusion blow and injection molding ngokomgaqo wenkqubo. Umgaqo ikakhulu uquka extrusion kuvuthela ukubumba, isitofu vuthela ukubumba, naliti ulwandiso vuthela ukubumba (eyaziwa ngokuba naliti ukuvuthela ukolula), multi- umaleko vuthela ukubumba, ukuvuthela sheet ukubumba, njl. vuthela umatshini wokubumba, kunye nokubumba ukuvuthela kufanelekile kuphela kwimveliso yeemveliso ze-thermoplastic. Ubume bombhobho wokuvuthela bulula, kwaye izinto ezisetyenziswayo zininzi zenziwe ngekhabhoni.

5. Extrusion die

Uhlobo lokubumba olusetyenziselwa ukuvelisa iimveliso zeplastiki ezinokwakheka okuqhubekayo, ezikwabizwa ngokuba yi-extrusion molding head, isetyenziswa ngokubanzi ekusetyenzweni kwemibhobho, imivalo, i-monofilaments, iipleyiti, iifilimu, iingcingo kunye nentambo yokuvala intambo, izinto ezineprofayili, njl.

Izixhobo zokuvelisa ezihambelanayo yi-extruder yeplastiki. Umgaqo-siseko kukuba iplastiki eqinileyo iyanyibilika kwaye iplastiki phantsi kweemeko zokufudumeza kunye ne-screw rotation ye-extruder, kwaye yenziwe kwi-cross-section efanayo njengemilo yokufa ngokusebenzisa i-die of shape ethile. Iimveliso zeplastiki eziqhubekayo. Izixhobo zayo zokuvelisa ziyintsimbi ye-carbon structural, izixhobo ze-alloy, njl.

Inkqubo ye-extrusion idla ngokufanelekileyo kuphela kwimveliso yeemveliso ze-thermoplastic, eyahluke kakhulu kwi-injection molds kunye ne-compression molds kwisakhiwo.

6. Ukungunda kwamadyungudyungu

Umngundo osebenzisa iipleyiti zeplastiki kunye namaphepha njengemathiriyeli ekrwada ukwenza iimveliso zeplastiki ezilula. Kwimeko yokuthambisa, ikhubazekile kwaye incamathele kumngxunya wokubumba ukuze ifumane imveliso ebunjiweyo efunwayo, esetyenziswa kakhulu ekuveliseni izinto eziyimfuneko zemihla ngemihla, ukutya kunye neemveliso zokupakisha zokudlala.

Ixesha lokuposa: Feb-12-2022