1. Injongo yovavanyo lokungunda?

Uninzi lweziphene ezibunjiweyo zenzeke ngexesha lemveliso yeplastiki kunye nenkqubo yokubumba, kodwa ngamanye amaxesha inxulumene noyilo lokubumba olungenangqiqo, kubandakanywa nobuninzi bemigodi; uyilo lwenkqubo yembaleki ebandayo / eshushu; uhlobo, isikhundla kunye nobukhulu besango lokutofa, kunye nesakhiwo sejometri yemveliso ngokwayo.

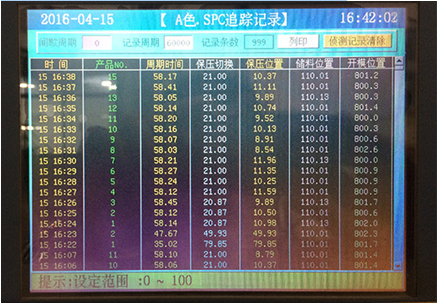

Ukongeza, ngexesha lenkqubo yovavanyo lwangempela, ukwenzela ukwenza ukungabikho koyilo lokubumba, abasebenzi bokuvavanya banokumisela ipharamitha engalunganga, kodwa uluhlu lwangempela lwedatha yokuvelisa ubuninzi obufunwa ngumthengi luncinci kakhulu, xa useto lweparameter kunye. Nakuphi na ukutenxa okuncinci, umgangatho wemveliso yobuninzi unokukhokelela kude ngaphaya koluhlu lonyamezelo oluvumelekileyo, kuya kubangela ukuba isivuno semveliso sibe sehla, ixabiso linyuke.

Injongo yolingo lokungunda kukufumana eyona parameters yenkqubo kunye noyilo lokungunda. Ngale ndlela, kwanezinto eziphathekayo, ipharamitha yomatshini okanye izinto zokusingqongileyo zinento etshintshileyo, isikhunta sisakwazi ukugcina uzinzile kunye nokuveliswa kobuninzi ngaphandle kokuphazamiseka.

2. Ulingo lokungunda Amanyathelo esiwalandelayo.

Ukuqinisekisa ukuba iziphumo zovavanyo lokungunda zichanekile, iqela lethu liya kuthobela amanyathelo angezantsi.

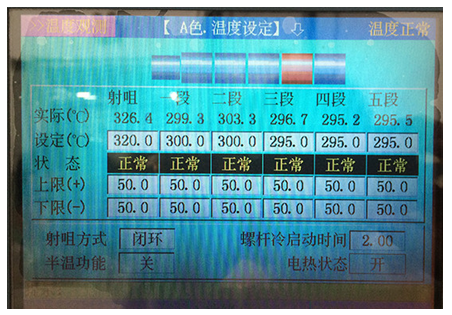

Inyathelo loku-1. Ukucwangcisa ubushushu bomshini wokutofa "umbhobho we-nozzle".

Kufuneka kuqatshelwe ukuba iqondo lokushisa lokuqala lombhobho kufuneka lisekelwe kwisincomo somthengisi wezinto eziphathekayo. Kwaye ke ngokwemiqathango ethile yemveliso yokulungiswa okufanelekileyo.

Ukongezelela, ukushisa kwangempela kwezinto ezinyibilikayo kwi-barrel kufuneka kulinganiswe nge-detector ukuqinisekisa ukuthotyelwa kwesikrini esibonisiwe. (Siye saba neemeko ezimbini apho umahluko wobushushu ukuya kuma 30 ℃).

Inyathelo 2. Ukumisela iqondo lokushisa lokubumba.

Ngokufanayo, ukusetwa kweqondo lokushisa lokuqala lokubumba kufuneka kwakhona kusekelwe kwixabiso elicetyiswayo elinikezwe ngumthengisi wezinto eziphathekayo. Ngoko ke, ngaphambi kovavanyo olusemthethweni, ukushisa kwendawo ye-cavities kufuneka kulinganiswe kwaye kubhalwe phantsi. Ukulinganisa kufuneka kwenziwe kwindawo eyahlukileyo ukubona ukuba iqondo lokushisa lilinganisiwe, kwaye urekhode iziphumo ezihambelanayo kwireferensi yokuphucula ukubumba.

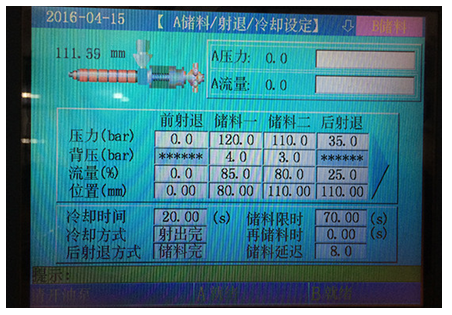

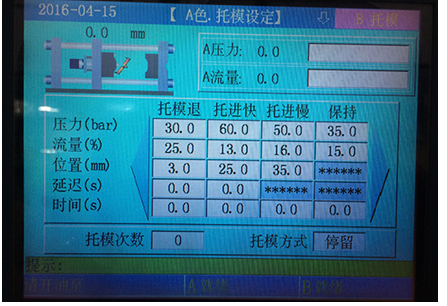

Inyathelo 3. Ukumisela iiparamitha.

Okufana nokufakwa kweplastiki, uxinzelelo lwenaliti, isantya sokutofa, ixesha lokupholisa, kunye nesantya se-screw ngokwamava, emva koko uyandise ngokufanelekileyo.

Inyathelo 4. Ukufumana indawo yokutshintsha "i-injection-holding" ngexesha lokuzaliswa kovavanyo.

Indawo yokutshintsha yindawo yokutshintsha ukusuka kwinqanaba le-injection ukuya kwisigaba sokubamba uxinzelelo, esinokuthi sibe yi-injection screw position, ixesha lokuzalisa kunye noxinzelelo lokuzalisa. Le yenye yezona parameters ezibalulekileyo kunye nesiseko kwinkqubo yokubumba inaliti. Kuvavanyo lwangempela lokuzaliswa, la manqaku alandelayo kufuneka alandelwe:

- Uxinzelelo lokubamba kunye nexesha lokubamba ngexesha lovavanyo ngokuqhelekileyo lubekwe kwi-zero;

- Ngokuqhelekileyo, imveliso izaliswe kwi-90% ukuya kwi-98%, kuxhomekeke kwiimeko ezithile zodonga lobunzima kunye noyilo lwesakhiwo sokubumba;

- Ekubeni isantya senaliti sichaphazela indawo yocinezelo, kuyimfuneko ukuphinda uqinisekise indawo yokucofa ixesha ngalinye xa isantya sokutofa sitshintshwa.

Ngexesha lokuzalisa, sinokubona indlela izinto ezizalisa ngayo kwi-mold, ngaloo ndlela sigwebe ukuba zeziphi izikhundla ezilula ukuba ne-air trap.

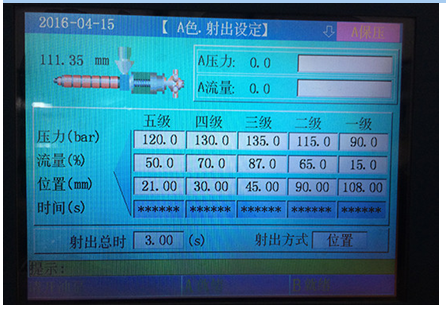

Inyathelo lesi-5. Khangela umda woxinzelelo lwenaliti yokwenene.

Ukusetwa koxinzelelo lwenaliti kwisikrini ngumda woxinzelelo lwenaliti yokwenyani, ke kufuneka ibekwe isoloko ingaphezulu koxinzelelo lokwenyani. Ukuba iphantsi kakhulu kwaye emva koko isondele okanye igqithwe ngoxinzelelo lwangempela lwenaliti, isantya sangempela sokutofa siya kuncipha ngokuzenzekelayo ngenxa yokunciphisa amandla, okuya kuchaphazela ixesha lokutofa kunye nomjikelezo wokubumba.

Inyathelo lesi-6. Fumana esona santya silungileyo sokutofa.

Isantya se-injection esibhekiselwe apha sisantya apho ixesha lokuzalisa lifutshane kangangoko kunokwenzeka kwaye uxinzelelo lokuzalisa luncinci kangangoko. Kule nkqubo, la manqaku alandelayo kufuneka aqatshelwe:

- Uninzi lweemveliso zokukhubazeka komphezulu, ngakumbi kufutshane nesango, zibangelwa sisantya sokutofa.

- Inaliti enamanqanaba amaninzi isetyenziswa kuphela xa inaliti yenqanaba elinye ingakwazi ukuhlangabezana neemfuno, ngakumbi kulingo lokungunda.

- Ukuba imeko yokungunda ilungile, ixabiso lokumisela uxinzelelo lichanekile, kwaye isantya sokutofa sanele, kukho isiphene seflash yemveliso akukho nto inxulumene ngokuthe ngqo nesantya sokutofa.

Inyathelo 7. Lungiselela ixesha lokubamba.

Ixesha lokubamba likwabizwa ngokuba lixesha eliqinileyo lesango lokutofa. Ngokubanzi, ixesha linokumiselwa ngokulinganisa. kubangele ixesha lokubamba elahlukileyo, kwaye elona xesha lifanelekileyo lokubamba lixesha apho ubunzima bokungunda bunyuswe.

Inyathelo 8. Ukuphucula ezinye iiparamitha.

Okufana nokubamba uxinzelelo kunye namandla okubamba.

Enkosi kakhulu ngexesha lakho lokufunda apha.ukwazi ngakumbi malunga nolingo lokungunda

Ixesha lokuposa: Jul-25-2020