I-1, Uyilo lwangaphambili lwe-deformation lungundoqo

Malunga nomoya we-auto kunye nemveliso yetanki yemveliso yeplastiki, ulawulo lomgangatho woyilo kunye nokuveliswa kunzima kunohlobo oluqhelekileyo, njengoko olu hlobo lwamacandelo luqhele ukubunjwa yi-PA6 (PA66) + GF (30-35%) ikhompawundi, kwaye oku uhlobo impahla kulula ukufumana deformation ngexesha lenkqubo yokubumba, kunye nobungakanani imveliso ehambelanayo kulula ukuba ngaphandle unyamezelo. Ke ngoko, ukuqhelana ne-deformation yayo yesiqhelo, emva koko ukwenza uyilo lwangaphambi kokuguqulwa okusekwe kumava kunye nesiphumo sohlalutyo lwe-CAE kwinkqubo yokuyila kwangoko ibe sisitshixo kwimpumelelo yokwenziwa komngundo.

Iqela le-Enuo mold lineminyaka engaphezu kwe-10 yamava ekwenzeni umngundo wangaphambili, kwaye bakhonze iValeo, i-Mahle-behr, iDelphi kunye nabanye abathengi beendawo zemoto abaziwayo kwihlabathi. Apha sazisa ngokufutshane amava ethu omoya we-auto kunye nokwenza umngundo wetanki yamanzi. Ngokuqinisekileyo, iinkampani ezahlukeneyo zineendlela ezahlukeneyo, ukuba umfundi othandekayo unezimvo ezahlukeneyo, wamkelekile ngokufudumeleyo ukunxibelelana nathi.

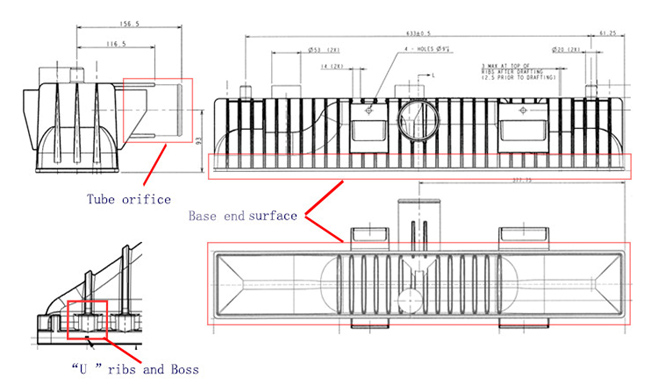

I-2, Ukuhlalutya imizobo yamacandelo, cacisa iindawo eziphambili zemveliso kunye nobukhulu

Ukuqonda imimandla ebalulekileyo yemveliso kunye nobukhulu obuphambili obunxulumeneyo ihlala ilinyathelo lokuqala xa imizobo yemveliso yabathengi ifika, emva koko unike ingqwalasela ethe kratya kwezo zinto zibalulekileyo, njengemveliso “Umphezulu wesiphelo” (“Umphezulu wesiphelo” wawufuneka kakhulu ngokuthe ngqo, ukuba tyaba. kunye nokunyamezela ubungakanani befom, kunye nezinye iindawo zomlinganiselo wemveliso ziya kulandela ukutshintsha kwazo),"Indawo yeTube orifice" (ubukhulu be "tube orifice" nayo ibaluleke kakhulu, ngokuqhelekileyo ukuma, ukunyamezelwa kwe-cylindrical kunye ne-dimensional kuyafuneka) kunye nemveliso " Umphathi” kunye “nemilo ka-U” iimbambo njl., ziboniswe apha ngezantsi:

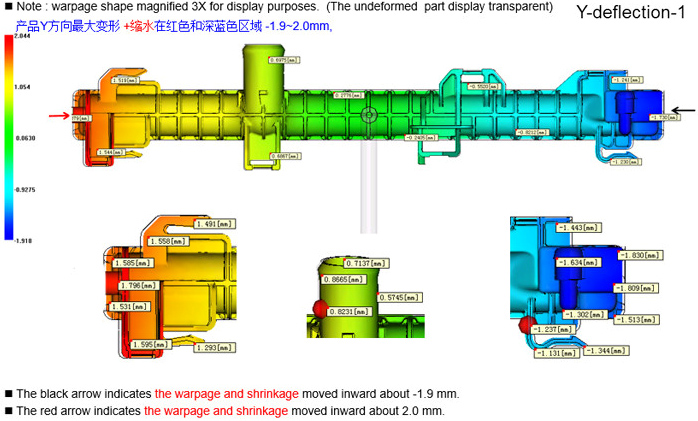

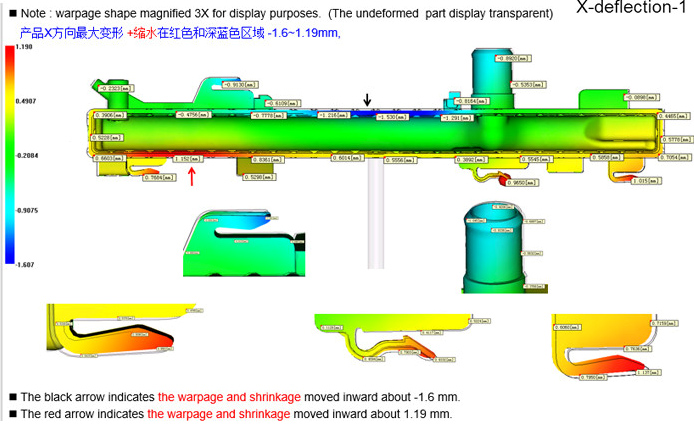

Kwi-mold entsha, yenza i-pre-deformation kwimveliso (ukwenza "imbuyekezo yezinto eziphathekayo" kwicala elichasene ne-deformation eqikelelwayo kwangaphambili ngokuhambelana namava kunye nohlalutyo lwe-CAE, cebisa ukuba ubenze bachanekileyo emva kokuba ukuguqulwa kwangempela kwenziwe). Emva kovavanyo lokubumba, ukwenza ukuguqulwa okuncinci okusekwe kwi-deformation yangempela yokubumba imveliso, ukulungisa ijometri yeplastiki, imilo kunye nesikhundla njalo njalo.

3, Ukuzoba iimveliso.

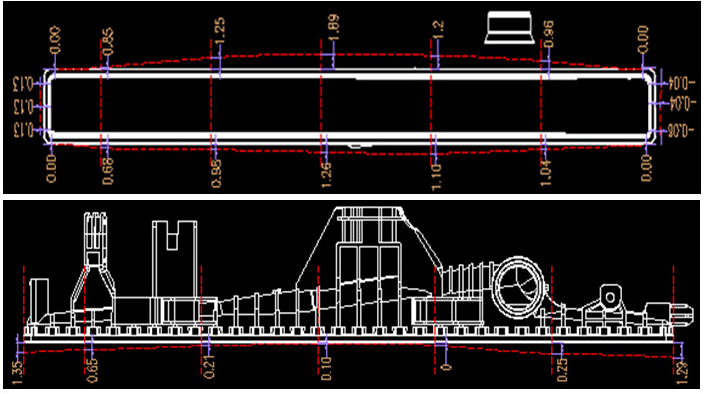

Ukuququzelela i-mold optimization yexesha elizayo, ukuzoba idatha entsha yemveliso ye-3D ngokwethu ngokwemveliso yomthengi iyimfuneko (iiparamitha ezibalulekileyo kufuneka zigcinwe). Ukumisela ixabiso le-deformation yemveliso, edityaniswe nohlalutyo lokuhamba kwe-mold kunye namava okuguqula idatha yemveliso, ngezantsi unokubona iindlela zokuguqula ezinamava:

Apha, ezinye iingcebiso ziyavuya ukuba kwabelwane ngazo ngexesha lenkqubo yokuzoba ngokutsha, njengale: soloko uqala ukuzoba indawo ethi "Base end surface", ngokwexabiso le-deformation ukuzoba ngokuthe tye, i-flatness curve emphethweni wemveliso, bhekisa kuloo magophe. ukuya “Yolula”(UG command) indawo ethe tye. Imiphezulu ethe tyaba yenziwa nge "Border" (UG command). Eli nyathelo libalulekile, ukuququzelela utshintsho lwexesha elizayo, udwebe ijika kuqala, musa "ukwelula" (umyalelo we-UG) ngokuthe ngqo, emva koko usebenzisa i-deformation surface of straightness fumana imveliso imilo nge "Offset" (UG umyalelo). Ukunqanda ukutshintsha iindawo ezininzi zokubumba ngexesha lokubumba okulandelayo, ukwenza ukusika izinto zeplastiki kwindawo yemveliso "Isiseko sesiseko somphezulu", emva koko uzibuyisele kwi-T1-T3 yokuguqulwa ngokusekwe kowona mgangatho wemveliso (kunye neplastiki).

Iingcebiso paybe luncedo:

1. Musa ukukopa iprofayile yeemveliso zabathengi kangangoko unako, zama ukuzizoba ngokwenu. Ke, kolu tshintsho lokungunda lulandelayo kulula ukuba lutshintshwe, kubandakanya ubukhulu bodonga. ukuba iimilo zikopi kwimveliso yabathengi emva kohlengahlengiso oluninzi, idatha ye-3D iya kufumana ukugqwetheka.

2. Kwinkqubo yokudweba, kangangoko kunokwenzeka ukujonga idatha yemveliso ye-2 / 3D yomthengi ukukhusela ukuba bahluke.

4,Indlela enokwenzeka yoguquko malunga nenxalenye ebalulekileyo yemveliso

1, Ukuguqulwa kwemveliso "Isiseko somphezulu wesiseko"

Kangangoko kunokwenzeka ukwenza isenzo sokunciphisa kwizinto zeplastiki ekuqaleni, kunokuphepha ukwenza kwakhona iindawo zokubumba kangangoko kunokwenzeka. Umgca obomvu ongezantsi ubonisa imveliso eqikelelweyo ye-deformation trend. Nceda uqaphele iimbambo “zoMphathi” okanye “ezimilise ngo-U” okanye imathiriyeli enxulumeneyo kufuneka zihanjiswe kunye “nesiseko sesiphelo somphezulu” kunye (Ezinye zezinto eziphantsi komphathi zehla nge-0.5mm, emva koko i-“Boss” ifanele ihle ngo-0.5 ), baze bazobe abanye. Kuyacetyiswa ukuba usebenzise "umphezulu" (umyalelo we-UG) ukuwazoba.

2, Ukuguqulwa kwemveliso ye "Tube orifice"

Ubume be-radius "R" kwingcambu yombhobho kufuneka bufane ncamashi nedatha yemveliso yabathengi, njengoko le "R" radius ichaphazela amandla ommandla obalulekileyo wemveliso. Kwiimeko eziqhelekileyo, ityhubhu engqukuva kufuneka incitshiswe iplastiki ngecala kuqala, emva koko utshintshe ixabiso ngokweyona nto iguqukileyo, kwityhubhu enkulu, imilo yetyhubhu mhlawumbi iyilwe njengemilo ye-oval kwangaphambili.

3, imveliso "U" imilo yeplastiki bit deformation

"I-U-shape" iplastiki kufuneka yenze malunga ne-2-3 degrees deformation, indawo ephakathi ye-"U-shape" iimbambo kufuneka inqumle izinto ezisecaleni (umfanekiso 1). Emva kokuba zonke iimveliso zizotywe kakuhle kwaye ukuyila irediyasi "R" (kwakhona ukuququzelela utshintsho, ngamanye amaxesha "R" ukwakhiwa kwakhona kwerediyasi kuya kusilela okanye ixesha elide lichithwe), ukuba ezinye iijometri kwidatha yomthengi we-3D ayizange iphazamise, singakwazi. chamfer kubo ukuba azichaphazeli iindibano amalungu (abathengi abaninzi bakhetha imilo ebukhali ukuba chamfered nge "R" radius). Ukongezelela, ezinye zejometri ezibalaseleyo kumzimba oyintloko wemveliso zinkulu , olu hlobo lokuguqulwa kwemveliso kufuneka luhlawule ingqwalasela ngakumbi kwi-parallelism kunye ne-perpendicularity (umfanekiso 2).

5, Isiphelo

Apha ngasentla ngamava ethu kuyilo lomoya wemoto kunye netanki yamanzi- "ukuguqulwa ngokulula" ngundo lwemveliso. ukugqiba eli nyathelo lilungile, ndicinga ukuba isiqingatha sempumelelo yokwenziwa komngundo singafumaneka, ke siphi esinye isiqingatha? nceda ubone icandelo elilandelayo leli nqaku "Ngaba uyayazi indlela yokwenza i-pre-deformation mold?-icandelo lokuvelisa" kwiveki ezayo.

Kulungile, bafundi abathandekayo. enkosi kakhulu ngexesha lakho lokufunda apha.ujonge phambili ukukubona kwicandelo elilandelayo!

Ixesha lokuposa: Jul-27-2020